Self Driving Chute

Keefam® Gravity-Driven conveyor Chutes

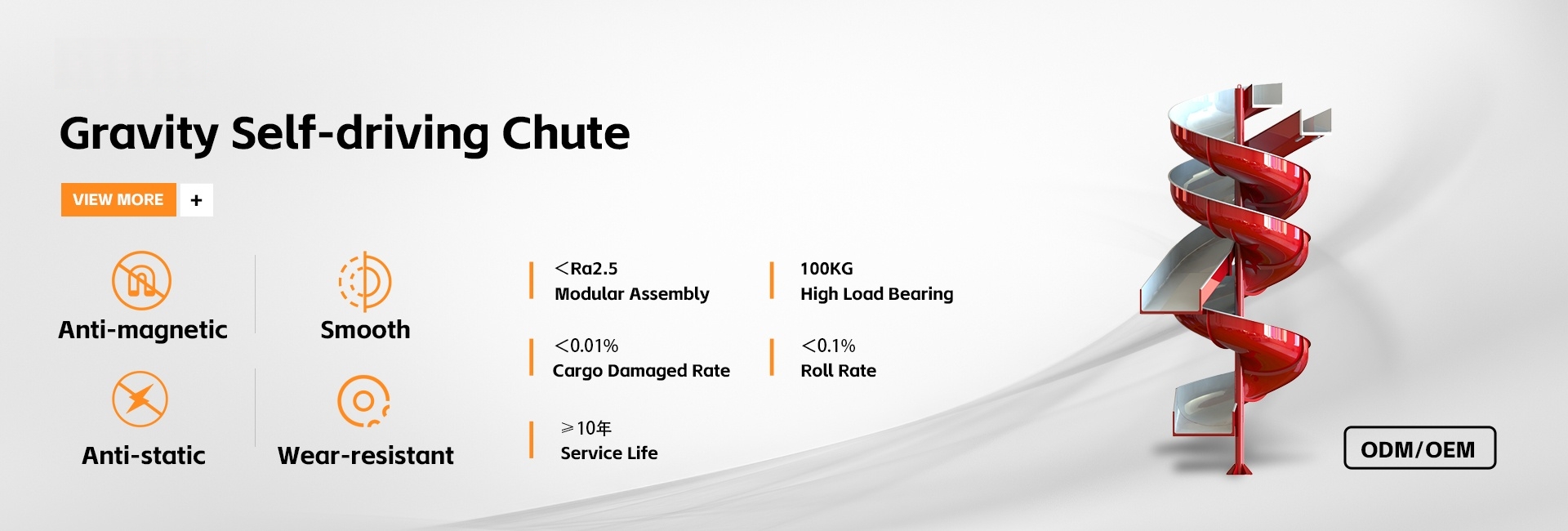

Crafted with advanced 3D monocoque molding technology using fiberglass composites, our chutes feature anti-magnetic and anti-static properties, ensuring safe handling of magnetic, soft, and irregular-shaped items.

Powered by proprietary motion algorithms, they generate multi-dynamic resistance curves for complex scenarios like multi-inlet systems, large spirals, and confined spaces. Modular spiral segments enable rapid assembly and transportation, outperforming traditional chutes in smoothness, energy efficiency (zero power consumption), and eco-friendliness.

With over a decade of expertise, we’ve delivered customized spiral chute solutions to 100+ global clients. Contact us to elevate your logistics efficiency today.

Cross Belt Conveyor Chute

Cross With Lattice Conveyor Chute

Cross With Lattice Conveyor Chute

Composite material one molding production, smooth surface, anti-magnetic, anti-water, anti-static

High Drop Spiral Conveyor Chute

Cross-Type Double-Entry Spiral Conveyor Chute

Cross-Type Double-Entry Spiral Conveyor Chute

Multi-Entry Spiral Conveyor Chute

Multi-Entry Spiral Conveyor Chute

Single Entry Spiral Conveyor Chute

Single Entry Spiral Conveyor Chute

Double Entry Spiral Conveyor Chute

Composite material one molding production, smooth surface, anti-magnetic, anti-water, anti-static

Low Drop Conveyor Chute

Diamond Conveyor Chute

Composite material one molding production, smooth surface, anti-magnetic, anti-water, anti-static

Manual One Point Two Conveyor Chute

Composite material one molding production, smooth surface, anti-magnetic, anti-water, anti-static

Composite material one molding production, smooth surface, anti-magnetic, anti-water, anti-static

Gravity Chute is a type of equipment used for the gentle, efficient, and controlled movement of bulk materials or items from one level to another in a continuous, gravity-driven process. It is commonly used in various industries, including logistics, warehousing, manufacturing, and food processing, where products need to be moved between different elevations without causing damage. Gravity spiral chutes with composite material one molding production, smooth surface, anti-magnetic, anti-water, anti-static; Automatic sliding, can effectively reduce energy loss and damage of goods. A variety of continuous motion surfaces can realize automatic and safe transportation of goods in complex environments.

We are an experienced custom spiral chute supplier. Please contact us to customize a spiral chute for your application.

Spiral Chute Features

1. 3D integrated molding process

Angle deviation < 1°, cargo transport 0 tumbling

2. Anti-magnetic anti-static

Good electrical insulation performance, friendly to 3C magnetic products

3. Super smooth

Nano-composite surface, roughness < Ra2.5

4. High space utilization

Support cargo transportation in complex environments such as small space and multiple entrances

5. Ultra-wear-resistant

Excellent quality of life ≥10 years

6. High hardness

New fiberglass matrix, standard bearing capacity 100KG/㎡

7. High weather resistance

No softening deformation in extreme environment, no flame, no burning

8. Easy installation

Flange installation mode, greatly reducing maintenance costs

Custom Spiral Chutes Technical Parameters

| Category | Name | Length(mm) | Width(mm) | Height(mm) | Entrance width(mm) | Exit width(mm) | Inner width(mm) |

| Manual sorting spiral chute | One entrance to one exit | 3420 | 2550 | 3100-500 | 1000 | 1000 | 1000 |

| One entrance to two exits | 3420 | 2550 | 3100-1800/500 | 1000 | 1000 | 1000 | |

| Manual loading chute | 3850 | 1850 | 3100-900 | 1000 | 1000 | 1000 | |

| Automatic sorting chute | Automatic upper sorting chute | 2905 | 1650 | 3100-1800 | 2000 | 1200 | 1200 |

| Automatic lower sorting chute | 2905 | 3630 | 3100-500 | 2000 | 1200 | 1200 | |

| Automatic upper sorting combined chute | 3150 | 2550 | 3100-1800 | 2000 | 1800 | 1200 | |

| Automatic lower sorting combined chute | 4830 | 2550 | 3100-500 | 2000 | 1800 | 1200 | |

| Large spiral chute | Single entry large spiral chute | 3820 | 3420 | 5200-900 | 1260 | 1260 | 1260 |

| Double entrance large spiral chute | 3820 | 3420 | 5200/3000-900 | 2200 | 1260 | 1260 | |

| Three entrance large spiral chute | 3820 | 3420 | 7400/5200/3000-900 | 2200 | 1260 | 1260 | |

| Loading large spiral chute | 3820 | 3420 | 5200-900 | 2200 | 1260 | 1260 |

Whole Process Quality Inspection

The company has ISO9001 international quality system certification, strict testing process, from raw material warehousing, production process control to finished products out of the warehouse, each link is strictly quality control, to ensure that product quality meets national standards and customer requirements; Professional inspection team, team members have rich industry experience and professional skills, can accurately judge product quality problems, and put forward improvement measures in time; The company pays attention to the construction and improvement of quality management system, through continuous improvement and innovation, improve product quality level and production efficiency, to meet the increasing needs of customers.